SaniTube© refurbishes rising main in Wakefield, England.

- Amex Sanivar

- Feb 18, 2021

- 2 min read

Updated: Nov 8, 2022

Overview

Wakefield is a city in West Yorkshire with a history dating back well over 2,000 years. With close to 350,000 inhabitants, it is also one of the largest city in the region. With a history of every growing infrastructure, when a pipe needs to be repaired, it can present numerous challenges. This was the case in late 2020.

Yorkshire Water is one of the largest water companies in the UK, supplying much of Northern England with water. In late 2020, Yorkshire Water realized the need to rehabilitate a Rising Main water pipe in Wakefield, England.

Amex Sanivar’s SaniTube© liner was chosen for the job by Sanivar UK and executed with support from Peter Duffy Ltd.

“ Thank you for your support with this project, prior, during and after and all in all it was a great success and really pleased with how its gone and can again see the benefits and speed of this repair method ”

Ben McLuskey- Lining Manager, Peter Duffy Ltd.

Challenges

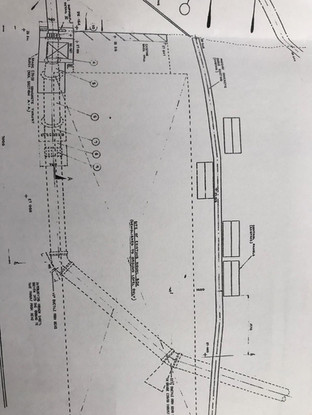

This 250m section of pipe was badly corroded and previous repairs had been unsuccessful. With the pipe also crossed the River Calder, creating pollution concerns from the exposed section of pipe, particularly when the exposed section of pipe became pressurized. The particular challenges this job posed were, first, access to the Rising Main was restricted due to the proximity of the mainline railway and all work had to be conducted under Network Rail supervision.

Second, given the proximity to the rail station, there were many bends that needed to be navigated, changes in diameter to be accounted for, and a 25m change in gradient over the railway embankment.

Finally, the liner also had to navigate a redundant chamber that because of its location on the embankment could not be accessed. From this point the main effectively became a gravity sewer feeding into a manhole before feeding the Treatment Works.

Outcomes

SaniTube© was proposed because it could navigate the bends, changes in diameter, and the variance from gravity to pressure pipe – all in the same 250m. Due to great planning and creative thinking, the liner was able to pass through only 30m of bends as the liner was pulled from the Southern section. The liner was pulled through in under an hour and then left overnight to allow the liner to rest in the gravity section of the pipe. The following day the line was able to be reinstated and the trenches backfilled.

SaniTube Specifications

How it works

· SaniTube® consists of a textile liner, and a double-sided thermoplastic coating

· Suited for the rehabilitation of all common types of pipes DN50 to DN450

· Suitable for great variety of media: potable water, sewage, industrial applications, gas, oil, and petrol

· SaniTube® is pulled-in via standard winch and reconnected to host pipe using a flange coupling

Main advantages

· Rehabilitation of up to 3000m in a single pull – incl. bends of up to 40°

· Design life of 50 years

· No resin, no impregnation, and no curing needed

· High resistance to pressure: burst pressures of over 34 bar w/o host pipe and resistant to vacuum

· Easy installation & no need for special equipment

Comments